Concrete Reinforcing Bar – A Method for Marking Reinforcing Bar

Identification marks on reinforcing bars are now requested by several international standards. Marks must be rolled onto one side of the bar to denote the producer’s mill designation, bar size, type of steel and minimum yield designation, etc.

Identification Marks

The identification marks are different for each specification, but a combination of letters and numbers is generally required today, this replacing the traditional method of identification by means of modifying the geometry of the notches rolled on the bar. In view of this growing demand for sophisticated marks, rebar producers are looking for equipment able to reach the performance and the quality requested by the market at minimum cost.

How Can These Be Applied?

A new marking philosophy using a machining head mounted on a modern CNC notching machine achieves this goal of a low cost, accurate and flexibility marking tool.

Marking Technologies

If we dismiss hand marking, used even day in some plants - which is in general carried out using grinding wheels sometimes with the help of a mechanical pantograph, the most popular marking is based on the principle of electro discharge machining to mark the roll and thus imprint the resulting rebar.

Marking Using Arc Metal Dischargers

The action of an arc metal discharger is achieved by creating a sequence of intermittent electric arcs to break the metal into minute particles. A hollow branding electrode, fixed on the head of the machine vibrates during the operation while a coolant is injected through the electrode to clean away the powered metal and to cool the working area. The hole created by the arc takes the same shape as the shell of the electrode. Thus the correct mark can be produced by using a sequence of appropriately shaped electrodes.

Modern Arc Machines

Modern arc machines are equipped with programmable repeatable positioning to speed up the location of the electrode along the sequence of grooves in the roll. Since the size and shape of the burned area is the size and shape of the electrode shell it is necessary to use a specific set of electrodes for each rebar size and for each letter/number.

Time to Mark Rolls

The time to burn in each letter approximately 0.6mm deep ranges from less than a minute in cast iron rolls to several minutes in tungsten carbide coated rolls. The overall marking time is much greater than this as several other time demanding manual operations must be performed:

· Roll handling from notching machine to marking machine;

· Electrode centering on the groove and positioning for each letter

· Electrode change for each letter.

Accuracy of Arc Machines

In addition, the accuracy of the surface finish of the mark made by this method is limited by the characteristics of the technology. With the growing demand for quality, this can become a limit in its application.

Electrical Discharge Machining

An alternative to such electro arc disintegrators, sink die Electrical Discharge Machining (EDM) is frequently used. In this case the electrode is solid, and work piece submerged in a dielectric fluid.

Operating Principal

The operating principle is almost the same as before. During operation, the electrode is moved toward the work piece until the space is such that the voltage in the gap can ionize the dielectric fluid and allow an electrical discharge (spark) to pass from the electrode to the work piece. The amount of material removed from the work piece with each pulse is directly proportional to the energy applied, enabling very accurate mark profiling to be achieved if the parameters are properly set. From the quality aspect, EDM meets today’s specifications.

Advantages of EDM Machines

EDM machines are in general more accurate and sophisticated and use two axes CNC to guide the head. They can also work with shaped electrodes, for example shaped to a logo, which reduces the time for indenting. However, the reference plane of the electrode is on a radius that must be equal to the radius of the roll. This ensures more accurate marks produced in a shorter overall time compared to disintegrator machines. A limit in the flexibility of this method is that different electrodes must be used depending on the radius of the roll groove which changes with roll wear and product size.

Processing Tungsten Carbide

Burning marks into tungsten carbide with disintegrators and EDM machines is also still a risky operation because the rapid heating and cooling of the roll surface can cause cracks and micro-craters to appear on the roll surface depending on the machining conditions used. Such heat affected zones (HAZ) can induce cracks caused by tensile stress in a brittle material such as tungsten carbide.

Integrating Notching and Marking

The integration of the two operations of notching and marking into the same machine has been a request from roll shop people for many years. Recently this demand became more urgent due to the growing requirement in international standards for accurate marking.

Problems Integrating EDM

Several difficulties had postponed the combination of a marking device within the roll notching machine. The original approach was to install an EDM in the notching machine. This solution encountered several obstacles. First, the EDM process generates electrical currents that could affect the electronics of the new sophisticated notching machines as well as cause local galvanic corrosion on the moving components. Second, the EDM process uses a liquid dielectric. This required a redesign of the notching machine to collect and recycle this liquid.

A New Approach

A new approach to the problem was investigated with the following aims:

· Make a new device as simple as possible so as to be able to install it on existing machines.

· Improve the quality and the consistency of marking

· Provide the flexibility to meet the different types of marks requested by the market.

· Minimise the time of operation and in particular the operator’s costs.

How It Works

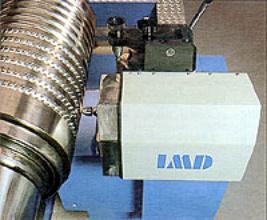

The prototype of such a device was built and tested in the first half of 2001. The IMD is now fitted as standard on all new AT820 E CNC notch milling machines, and can be retrofitted to any AT820 already in operation.

The working principle of IMD is by machining with cutting tools rotating at a medium speed. The rotation is provided by an electric blushless digitally controlled motor.

The device is installed on the notching head of the machine (Fig 1). The CNC control is common to both the notching head and the IMD.

|

|

| Figure 1. An IMD marking head mounted on a notching machine. |

The software for the IMD is fully integrated on the same platform as the notching machine. A new graphics interface displays all the functions to use both the notching machine and the marking head.

Flexible Programming

The IMD marking head can be easily integrated in the notching programs. The operator screen enables the following parameters to be selected:

· Positioning of letters: between notches or in the place of skipped notches

· Choice of fonts

· Depth of letters

· Height and width of letters as a percentage of the groove dimension

· Angle of the letters

· Tool parameters (tool feed, rotation speed etc).

The parameters requested for the dimension of the mark are not absolute values, but percentages of the groove dimensions. In this way the mark needs only to be defined once for the whole size range of production: a change of size does not require a change of mark program.

Tool positioning and marking operation are automatically performed at the end of the notching cycle, without any intervention by the operator.

Sometime it is required to indent a mark independently from the notching operation. This can happen, for example, when a logo must be marked on rolls already notched, or in a free area without any reference to the notch dimensions. In this case a special program leaves full freedom to the operator in define new marks. The user friendly graphical interface makes this programming extremely simple.

IMD Tooling

The IMD was developed for use on both tungsten carbide and cast iron rolls. It can safely be used on tungsten carbide rolls since the mechanical milling action does not affect its structure. Machining of hard carbides in this accurate application requires tools with PCD inserts, while for cast iron rolls WC (K01 grade) tools will do.

The same tool can create all the letters or logos required. The speed of marking is related to its characteristics. The parameters given in Table 1 are typical for cast iron and tungsten carbide.

Table 1. Typical operating speeds for different materials.

| | Cast Iron | Tungsten Carbide |

| Tool Rotation (rpm) | 1500 | 3000 |

| Feed Speed (mm/min) | 50 | 10 |

The ATOMAT mark illustrated in Fig 2 is cut into the groove of a tungsten carbide (30% binder) roll. The time taken to create the mark was approximately 12 minutes with the letters cut 0.8mm deep. Accuracy and consistency is assured by the machining technology and the computerised control.

|

|

| Figure 2. Example identification mark on an 8’ roll for processing 16mm rebar. |

Composite Logos

One problem of any marking programming is that it is impossible to foresee all possible logos that may be requested by a customer. In fact, often the mark is not a simple combination of letters and numbers but includes a company’s logo.

This problem is solved by developing software able to translate the ISO file (geode) into a parametric file that can be used by the IMD interface. The logo can be designed on CAD and translated by CAM into an ISO file. Software converts this ISO file into a parametric file usable by the interface. In this way, once the logo is designed and translated, its dimensions can be defined in accordance to the specific rebar size. Thus, it not necessary to design several logos one for each size, but just to input the dimensions and the software will automatically re-scale the logo to the new dimensions.

<< Home